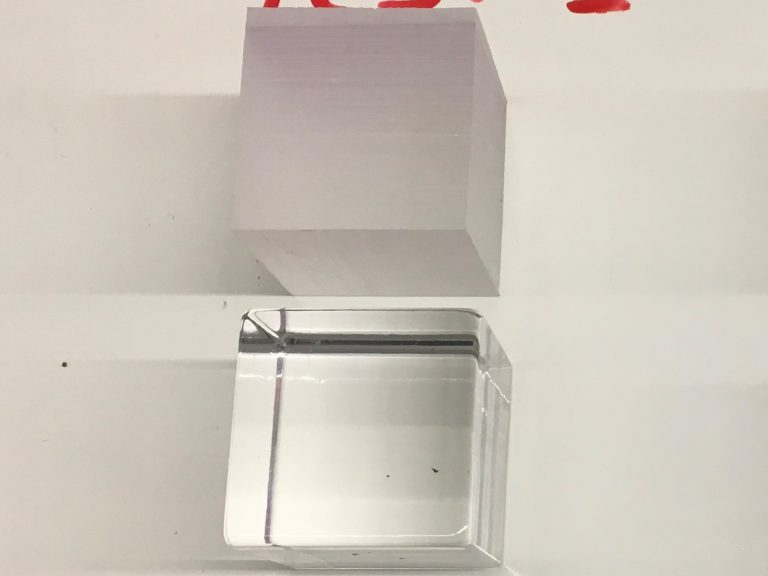

To create showroom samples or small granite tiles, larger pieces of granite are saw cut to the desired size and shape. The surface is often dull and the edges are sharp and square. The desired final result is a slightly rounded edge and a highly polished surface finish.

In order to get these results, two steps are required. The first step is designed to round the edges and remove any imperfections on the surface. The second step will polish that matte finish to a high, consumer-ready sheen.

Rounding the edges and removing cutting lines, scratches, or other imperfections is similar to the process used for metal parts. Tumbling with Ceramic Media and a general purpose tumbling compound provides the necessary abrasiveness. This will leave the granite piece with a smooth, matte finish.

Once the proper shape of the part is achieved, a second tumbling step is needed to polish. For granite and other stone products, tumbling with a Hardwood Media and the Hi-Gloss Final Finishing Cream provides the optimal result. While this can be done in both a vibratory or barrel tumbler, we find that barrel tumbling provides just the right tumbling action to provide the best finish on granite tile pieces.