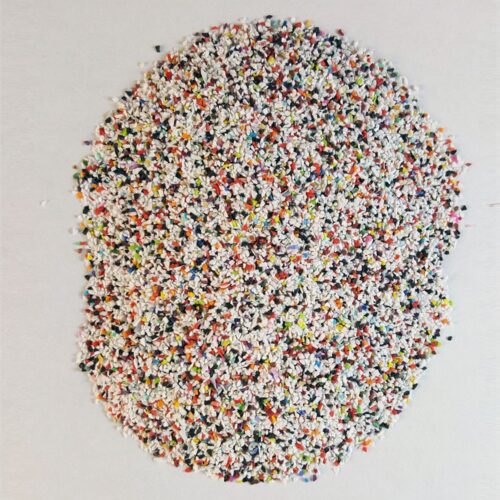

Urea (Type II) Plastic Abrasive Grit

Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface.

Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface.

Urea (Type II) Plastic Abrasive Grit

Urea Plastic Blast Media is a plastic grain stripping abrasive used in sandblasting operations. It is the most widely used plastic media. Urea Plastic Abrasive Grit is environmentally friendly and recyclable – an alternative to chemical stripping. It’s clean, it’s consistent, and it’s the most widely used plastic media for a reason. Urea Plastic Abrasive Grit is formulated to meet an increased level of stripping performance where stripping speed outweighs other considerations. Urea Plastic Abrasive Grit is able to strip tough coatings with an impressive strip rate. Urea Plastic Abrasive Grit is typically used for less sensitive applications.

Benefits

- Durable and Reusable

- Medium Hardness (MOH 3.5)

- Low Dusting

- Does Not Generate Heat During Blasting

- Suitable for Multiple Substrates

- Meets MIL-P-85891

Applications

- Rubber Molds

- Urethane Bumpers

- Aircraft engine components

- Auto / Bus / Truck Bodies

- Helicopters

- Tanks

- Wheels

- Surface Sealants

- Airframes

- Aircraft Components

- Fiberglass Components

- Printed Circuit Boards

- Semiconductors

- Soft Metals Such as Aluminum and Magnesium

- Carbon Graphite Composites

- Axial Lead Diodes / Capacitors / Clear Optical Sensors

- Computer Housing Panels

- Copper Armature Wires

- Metal Die-Castings

- Steel

- Gears

- Tire Molds

- Actuator Assemblies

Urea blasting media isn’t just a safe alternative to harsh chemicals—it’s a high-performance solution for complex surfaces and sensitive components. It’s ideal when speed matters, but surface integrity matters more.

Urea plastic abrasive is manufactured to tight tolerances in particle size. It ensures consistent stripping performance and a uniform surface finish. This is especially important for precision work in aerospace and electronics industries.

From aerospace to automotive, from soft metals to circuit boards, urea plastic blast media handles it all with surgical precision and no side effects. If you need a blast that works hard without working rough, this is your grit.

Looking for a clean, capable, and cost-effective way to strip coatings fast? Kramer Industries delivers top-tier urea blasting media built to meet demanding specs with ease. Discover our full range of urea plastic blast media today.

Specifications

Frequently Asked Questions (FAQs)

Q1. What is urea plastic blast media?

Urea plastic abrasive blast media is a thermoset plastic abrasive made from urea-formaldehyde resin. It is designed for non-destructive blasting, especially where substrate protection is crucial, such as in aerospace, automotive, and electronics industries.

Q2. What is urea blast media used for?

Urea blast media is primarily used for:

- Paint stripping from aluminum or composite surfaces

- Deflashing plastic parts

- Cleaning molds or delicate tooling

- Aerospace and military coating removal without substrate damage

Q3. What are the advantages of urea plastic media over traditional abrasives?

- Low hardness reduces risk of surface damage

- Minimal dust and residue

- Reusable and durable

- Ideal for precision applications

Q4. Is urea plastic blast media reusable?

es, it is highly reusable—often lasting for multiple blast cycles (10–30 passes), depending on the pressure, media recovery system, and application.

Q5. What equipment is compatible with urea plastic media?

Urea plastic media works best in pressure blast cabinets, suction cabinets, and automated blasting systems that support media recycling.

Related Products

-

SS Series – Industrial Grade, Suction Style, Abrasive Media Blasting Cabinet

$995.00The SS Series, Industrial Suction Sandblaster Cabinet is the most economical and commonly used blast cabinet. Designed for small shops and light production areas, the siphon/suction systems are ideal for quick blasting and surface prep. The SS Series can be used with all types of dry abrasive blast media.

-

Melamine (Type III) Plastic Abrasive Grit

$49.95 – $170.00 Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance.

Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance. -

Acrylic (Type V) Plastic Abrasive Grit

$54.95 – $255.00 Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts.

Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts. -

Walnut Shell Blasting Media Grit

$39.95 – $105.00 Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media.

Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media.