ABRASIVE MEDIA FOR SANDBLASTING EQUIPMENT

Abrasive media for sandblasting equipment is used for a wide variety of applications including sand blasting, tumble deburring, polishing, and other surface finish processes. As a wide range abrasive finishing company, many media are available in a wide range of types, hardness, grit and mesh sizes, and abrasiveness.

Types

- Heavy Abrasives for High Cutting Action

- Organic Media for Polishing and Light Abrasiveness

- Soft Media for Protection of Substrates During Blasting

- Multiple Grit/Mesh Sizes in Every Media Type

- Reusable Media With Long Usable Lifetimes

- Consumable and Affordable Blasting Media

Applications

- Cleaning

- Paint and Coating Striping

- Deflashing

- Removing Machine Marks

- Sanding

- Edge Rounding

- Surface Preparation

- Scale and/or Rust Removal

- Non-Skid Coatings

Typical Uses

- Machine Mark Removal

- Rust Removal and Cleaning

- Surface Finish Modification

- Abrasive Blasting for Coatings Preparation

- Polishing in Tumbling Applications

- Abrasion Resistance in Coatings

- Creating Specific Surface Finishes

All media blasting techniques work according to a basic concept: small moving particles collide with a surface at high speed and remove surface particles or etch or peen the surface itself. Specific blasting media vary dramatically in terms of their intended purpose and method. One use of sandblasting media is to remove impurities prepare the surface in advance of paint or coating application.

Most abrasive finishing companies originally made use exclusively of silica particles for Sandblasting . Still, as research uncovered health risks associated with long-term exposure to the dust created by silica blasting, alternative media were developed abrasive finishing company. These abrasive blasting media, while minimizing health risks, were also discovered to outperform silica media in many applications.

Choosing the right abrasive blast media and the right abrasive finishing company is essential to finish surface preparation for paint or coating application. The following media types are available with various applications according to their hardness, size and abrasiveness.

Showing all 14 results

-

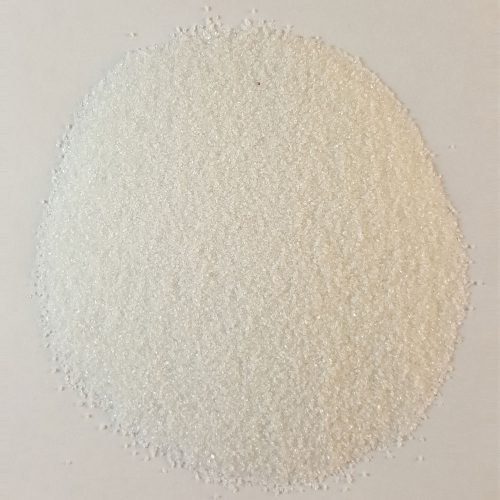

White Aluminum Oxide Grit

$39.95 – $265.00White Aluminum Oxide Grit is a >99% ultra-pure grade of abrasive media. It is increasingly being used in critical, high-performance processes that are sensitive to contamination and cleanliness.

-

Aluminum Oxide Abrasive Blasting Media Grit (Standard)

$39.95 – $244.50Aluminum Oxide Blasting Media Grit (Standard) is a sharp, long lasting abrasive media that is highly efficient and highly reusable. Harder than most blast media, Aluminum Oxide Blast Media, will clean and etch quickly on all type of surfaces.

-

Silicon Carbide Grit Blasting Media

$39.95 – $430.00Silicon Carbide Grit is the hardest abrasive media. This blasting media has very fast cutting action and can be recycled and re-used many times. The hardness of Silicon Carbide Grit allows for shorter blast times relative to other blasting media.

-

Walnut Shell Blasting Media Grit

$39.95 – $105.00 Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media.

Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media. -

Glass Bead Blasting Abrasive Grit

$39.95 – $94.50 Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring.

Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring. -

Corn Cob Media Grit

$39.95 – $90.00 Corn Cob Media is a biodegradable media this will not etch or warp thin-walled or soft surfaces. A low hardness and absorbent media ideal for many blasting and tumbling applications.

Corn Cob Media is a biodegradable media this will not etch or warp thin-walled or soft surfaces. A low hardness and absorbent media ideal for many blasting and tumbling applications. -

Steel Shot Blasting Media Abrasive

$59.95 – $134.50 Steel Shot is ideal for peening applications to impart a clean, smooth finish. This dense, smooth media can be used up to 3,000 times and produces minimal dust during the blasting process.

Steel Shot is ideal for peening applications to impart a clean, smooth finish. This dense, smooth media can be used up to 3,000 times and produces minimal dust during the blasting process. -

Pumice Grit

$39.95 – $84.50 Pumice is a natural mineral sourced from volcanic ash. It is a light, soft abrasive used in a wide variety of applications. As a natural product, variability from sources provides unique performance properties.

Pumice is a natural mineral sourced from volcanic ash. It is a light, soft abrasive used in a wide variety of applications. As a natural product, variability from sources provides unique performance properties. -

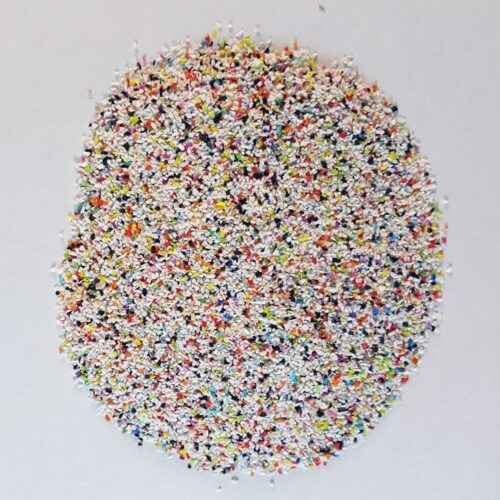

Melamine (Type III) Plastic Abrasive Grit

$49.95 – $170.00 Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance.

Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance. -

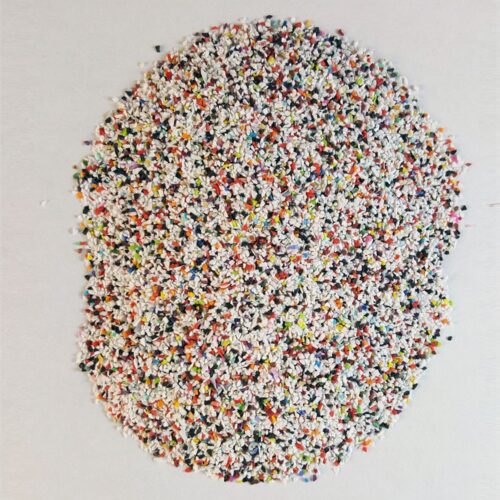

Urea (Type II) Plastic Abrasive Grit

$49.95 – $170.00 Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface.

Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface. -

Acrylic (Type V) Plastic Abrasive Grit

$54.95 – $255.00 Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts.

Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts. -

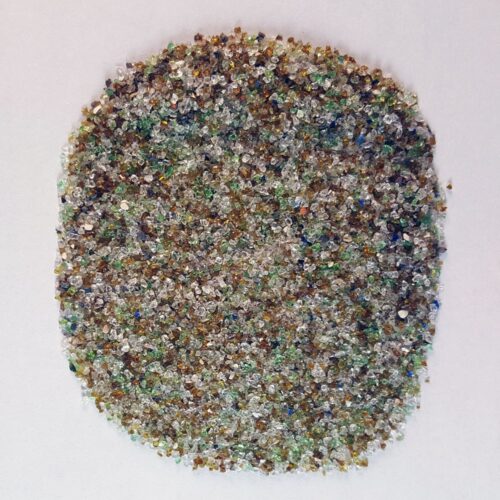

KramBlast Crushed Glass Grit

$21.95 – $35.00 KramBlast Crushed Glass Grit is a silica-free, consumable abrasive that offers aggressive surface profiling and coatings removal. Manufactured from 100% recycled bottle glass, KramBlast Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives.

KramBlast Crushed Glass Grit is a silica-free, consumable abrasive that offers aggressive surface profiling and coatings removal. Manufactured from 100% recycled bottle glass, KramBlast Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives. -

Garnet Grit Blasting Media

$39.95 – $87.00 Garnet Grit is a used for a wide variety of blasting applications. Used in both dry and wet abrasive blasting, Garnet Grit offers high performance and recyclability. The hardness and bulk density make this media ideal for general purpose surface preparation.

Garnet Grit is a used for a wide variety of blasting applications. Used in both dry and wet abrasive blasting, Garnet Grit offers high performance and recyclability. The hardness and bulk density make this media ideal for general purpose surface preparation. -

Steel Grit Blasting Media

$54.95 – $159.50 Steel Grit is an angular, carbon steel media designed for quick and effective removal of surface contaminants and coatings. Steel Grit is softer than other media and is less likely to fracture leaving an etched finish.

Steel Grit is an angular, carbon steel media designed for quick and effective removal of surface contaminants and coatings. Steel Grit is softer than other media and is less likely to fracture leaving an etched finish.