TUMBLING MEDIA FOR BARREL & VIBRATORY FINISHING EQUIPMENT

In the tumbling process, a preformed media is a rigid agent that abrades the given part and removes the unwanted material. The advantage of tumbling media is the inclusion of a bonding agent that continuously recedes and exposes more abrasive particles. As a result, they maintain a relatively consistent removal rate over at least half the size of their shape.

Your desired surface finish determines the needed characteristics of your chosen media, such as size, shape, internal particle size, and mineral composition. Oftentimes, a project requires a trial process before the development of a mass finishing project. We offer free test runs of your parts in our laboratory to assist in this manner. When finished, we return the parts for your evaluation.

When considering tumbling media for aluminum, the choice of media is critical when trying to achieve a specific finish without damaging the aluminum, which is a relatively soft metal. Tumbling media for aluminum should be selected to ensure it has the appropriate level of aggressiveness but is not too aggressive or abrasive to the aluminum parts. This is where understanding the properties of tumbling media for aluminum comes into play. The media composition or bond needs to be appropriate to tumble the aluminum with delicacy yet effectively, preventing any undue metal removal or warping of the parts. The tumbling media for aluminum is not just about abrasion; it’s about achieving the finish needed while preserving the surface quality and tolerances of the aluminum

parts.

Types

- Preformed Shapes and Sizes – Ceramic, Plastic, Synthetic, and Others

- Hardwood Media for Dry Tumbling

- Steel Media for Burnishing and Work Hardening

- Abrasives for Aggressive Deburring to High Polishing

- Treated Media for Light Cutting to Near Mirror Finishes

Applications

- Deburring

- Cleaning

- Deflashing

- Edge radiusing

- Polishing

- Burnishing

- Removing Machine Marks

- Sanding

- Scale and/or Rust Removal

Typical Uses

- Machine Mark Removal

- Rust Removal and Cleaning

- Polishing Metal and Plastic Parts

- Finishing 3D Printed Parts

- Sanding Wood Parts

- Deburring Metals and Plastics

- Deflashing Extruded Parts

Tumbling media is a preformed abrasive material that is used for finishing and polishing parts made of various materials. It is mainly used with finishing equipment so that tumbling media and parts scrub against each other, producing thorough and precise abrasiveness to remove burrs.

Showing all 13 results

-

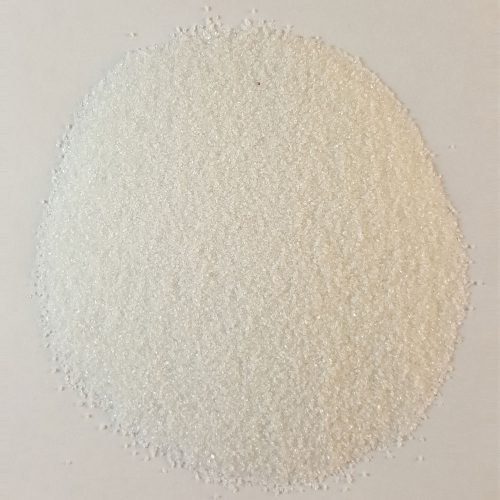

White Aluminum Oxide Grit

$39.95 – $265.00White Aluminum Oxide Grit is a >99% ultra-pure grade of abrasive media. It is increasingly being used in critical, high-performance processes that are sensitive to contamination and cleanliness.

-

Aluminum Oxide Abrasive Blasting Media Grit (Standard)

$39.95 – $244.50Aluminum Oxide Blasting Media Grit (Standard) is a sharp, long lasting abrasive media that is highly efficient and highly reusable. Harder than most blast media, Aluminum Oxide Blast Media, will clean and etch quickly on all type of surfaces.

-

Silicon Carbide Grit Blasting Media

$39.95 – $430.00Silicon Carbide Grit is the hardest abrasive media. This blasting media has very fast cutting action and can be recycled and re-used many times. The hardness of Silicon Carbide Grit allows for shorter blast times relative to other blasting media.

-

Hardwood Tumbling Media

$49.95 – $632.50Hardwood Tumbling Media is specially chosen and cut for optimal performance in dry tumbling applications. Used in combination with Finishing Creams, Hardwood Tumbling Media is utilized for deburring, surface smoothing, and polishing. Ideal for plastic parts.

Currently, NC-1, NP-11, NP-12, NP-13, ND-5 and ND-6 Diamond products are unavailable for shipping. We will notify you once the product is back in stock. -

Premium Ceramic Tumbling Media

$34.95 – $762.85Premium Ceramic Tumbling Media is designed for specific applications where precision deburring and polishing is required. The smaller sizes are ideal for intricate finishing jobs. Perfect for deburring and polishing in tight areas and smaller parts.

-

Walnut Shell Blasting Media Grit

$39.95 – $105.00 Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media.

Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media. -

Corn Cob Media Grit

$39.95 – $90.00 Corn Cob Media is a biodegradable media this will not etch or warp thin-walled or soft surfaces. A low hardness and absorbent media ideal for many blasting and tumbling applications.

Corn Cob Media is a biodegradable media this will not etch or warp thin-walled or soft surfaces. A low hardness and absorbent media ideal for many blasting and tumbling applications. -

Premium Treated Media

$39.95 – $18,585.00The line of Premium Treated Tumbling Media is formulated to produce superior results without the need for

water or added compounds. This process is called Dry Tumbling. These media are bases of Walnut Shell Grit, Corn Cob Grit, and others with added abrasives, lubricants, binders, and polishing agents. Please contact us if you need a non-standard stock item as these are sometimes readily available and/or can be produced quickly.

water or added compounds. This process is called Dry Tumbling. These media are bases of Walnut Shell Grit, Corn Cob Grit, and others with added abrasives, lubricants, binders, and polishing agents. Please contact us if you need a non-standard stock item as these are sometimes readily available and/or can be produced quickly. -

Stainless Steel Tumbling Media

$49.95 – $2,779.00Stainless Steel Tumbling Media is used for burnishing and polishing metals similarly to Carbon Steel Tumbling Media. Stainless Steel Tumbling Media reduces the need for rust inhibitors and limited storage requirements.

-

Plastic Tumbling Media

$3.27Plastic Tumbling Media is recommended for general purpose metal removal, pre-plate finishing, and moderate cutting. Plastic Tumbling Media is ideal for soft metals such as brass and aluminum or for stringy materials to avoid rolling the burr into a hole.

-

High Density Ceramic Tumbling Media

$3.66High Density Ceramic Polishing Media is a heavier, longer lasting media ideal for use when reduced cycle times and low residue processes are required. Both deburring and polishing formulations are available in a variety of sizes and shapes.

-

Ceramic Tumbling Media

$2.08Ceramic Tumbling Media is ideal as a general-purpose media and can be used with almost any type of material and part shape. It is best for harder metals and plastics and for more aggressive requirements. Ceramic Tumbling Media is available from polishing to ultra-aggressive bonds.

-

Carbon Steel Tumbling Media

$0.00Carbon Steel Tumbling Media is used for burnishing and polishing metals. The high bulk density exerts added pressure to a mass of parts producing a high shine in reduced finishing times. Carbon Steel Tumbling Media is also used for surface work-hardening.