Abrasive blasting is referred to by many as sandblasting. This robust procedure that demands much careful attention to detail, especially so when it comes to all the air specifications. Grasping how air volume (expressed in cubic feet per minute or CFM) and air pressure (expressed in pounds per square inch or PSI) affect your blasting nozzle size is essential. Choosing the appropriate air compressor guarantees efficiency. It minimizes equipment wear and tear and provides optimal outcomes.

Let’s explore in detail the particulars of air needs for abrasive blasting, the significance of compressor sizing, and how to utilize an air requirement chart to obtain optimal results.

Why Air Matters in Abrasive Blasting`

The air system serves as the foundation of every abrasive blasting operation. It drives the operation, pushes the abrasive substance through the nozzle, and influences the strength and distribution of the blast.

Here’s the reason air is so essential:

- Consistent Blasting Pressure: A lack of adequate air volume causes the blasting pressure to decrease. It lowers the effectiveness and quality of the blast.

- Smooth Operation: Sufficient air prevents the compressor from operating at maximum capacity all the time. This minimizes the wear and fuel usage.

- Faster Completion Times: A steady air supply ensures consistent blasting, which can cut down job times significantly, especially on heavy-duty tasks like removing scale or rust.

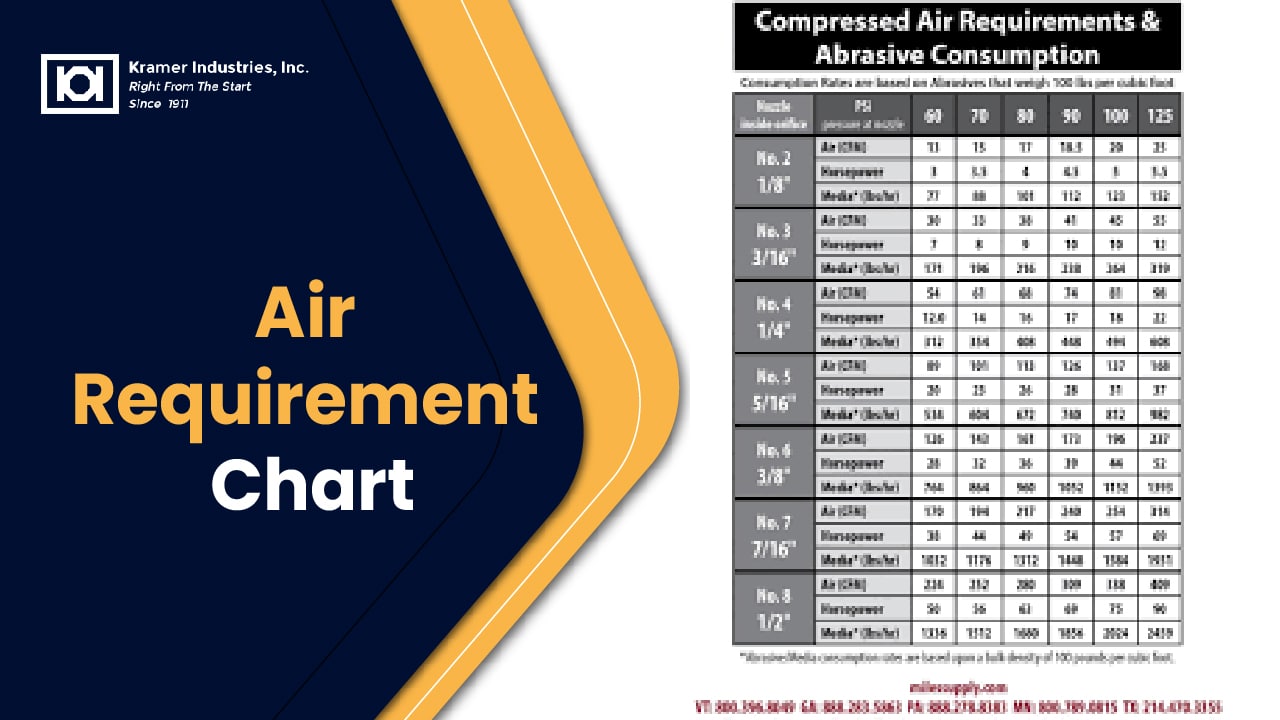

The Air Requirement Chart

Understanding the air requirement chart is the first step to selecting the right compressor. Below is a breakdown of nozzle sizes, air pressures, and the corresponding CFM requirements for your blasting needs: (From an excellent chart at ThePaintPro.com, one of the contractors that regularly posts on ContractorTalk)

| Nozzle Size | Air Pressure (PSI) | Air Volume Required (CFM) |

| 1/8″ (#2) | 90 PSI | 20 CFM |

| 3/16″ (#3) | 90 PSI | 40 CFM |

| 1/4″ (#4) | 90 PSI | 75 CFM |

| 5/16″ (#5) | 90 PSI | 125 CFM |

| 3/8″ (#6) | 90 PSI | 175 CFM |

| 7/16″ (#7) | 90 PSI | 240 CFM |

| 1/2″ (#8) | 90 PSI | 310 CFM |

Adjusting for Pressure Changes

Every 10 PSI increase or decrease in blasting pressure requires quite an adjustment in air volume by approximately 10%. For example:

- At 100 PSI, a 1/4″ nozzle requires 83 CFM.

- At 80 PSI, the same nozzle needs only 68 CFM.

This adjustment ensures you maintain the efficiency and effectiveness of your blasting process.

Choosing the Right Compressor

The air compressor acts like the heart of your setup. Select the right one by matching the CFM and PSI requirements of your nozzle to the compressor’s output capacity.

Rule of Thumb

Each horsepower (HP) of a compressor generates approximately 4 CFM of air. For example:

- A 25 HP compressor can produce about 100 CFM.

- A 50 HP compressor delivers around 200 CFM.

If your setup requires 175 CFM at 90 PSI (e.g., for a 3/8″ nozzle), you’ll need at least a 44 HP compressor.

Accounting for Pressure Drops

Blasting systems experience pressure drops due to air hose length, bends, and fittings. On average:

- Add a 3 PSI drop for every 50 feet of air hose.

- Additional bends or connections may increase the pressure loss.

To counteract this, choose a compressor that can maintain slightly higher PSI than required at the nozzle.

Insights from the Field: The Power of More Air

Experienced contractors swear by the adage: “You can never have too much air.” Larger compressors provide several benefits:

- Steady PSI Levels: A powerful compressor maintains consistent pressure, even during prolonged use.

- Reduced Fuel Consumption: Two compressors running at low idle burn less fuel than one running at full tilt.

- Faster Job Completion: More air means better blasting performance, cutting down time spent on heavy-duty tasks.

A recent string on ContractorTalk discusses this issue exactly. In a real-world example, a contractor used two 185 CFM compressors in tandem:

- With one compressor: Maintained 80 PSI, consumed half a tank of fuel in 5 hours, and required more effort to complete the job.

- With two compressors: Maintained 100 PSI steadily, consumed only 1/4 tank of fuel per compressor in 5 hours, and shaved 2 hours off the job time.

Thus, investing in a larger air compressor or pairing multiple units of them can quite improve efficiency and reduce operational costs.

Practical Tips for Maximizing Air Performance

- Select the Right Nozzle Size: Smaller nozzles require less air. They may not quite deliver the coverage or force needed for larger surfaces.

- Monitor Pressure Levels: Ensure consistent PSI at the nozzle. Regularly inspect hoses and connections for leaks.

- Plan for Pressure Loss: Factor in hose length and bends when setting your compressor’s PSI.

- Consider Dual Compressors: Hooking two compressors together can provide the additional air volume needed for demanding jobs.

- Regular Maintenance: Clean filters and service compressors to maintain optimal performance.

Final Thoughts

The air requirement chart serves to be more than a mere guide—it is quite essential for successful abrasive blasting outcomes. By understanding the connection between nozzle size, PSI, and CFM, you can get the appropriate compressor for your process and guarantee smooth operation. Regardless of whether you are addressing light-duty tasks or large-scale removals, having adequate air volume and pressure is essential.

Keep in mind that increased air is not merely a luxury—it is essential. Acquiring a strong compressor or linking several units can help save time, cut fuel usage, and extend the lifespan of your machinery. Field contractors have found that the proper air configuration turns abrasive blasting from a difficult task into an easy one. Therefore, don’t hold back on air—your outcomes will appreciate it.

Maximize your abrasive blasting efficiency with Kramer Industries! From selecting the right nozzle size to ensuring optimal air pressure, we’ve got the expertise and equipment to elevate your blasting projects. Contact us today to find the perfect solution for your needs!