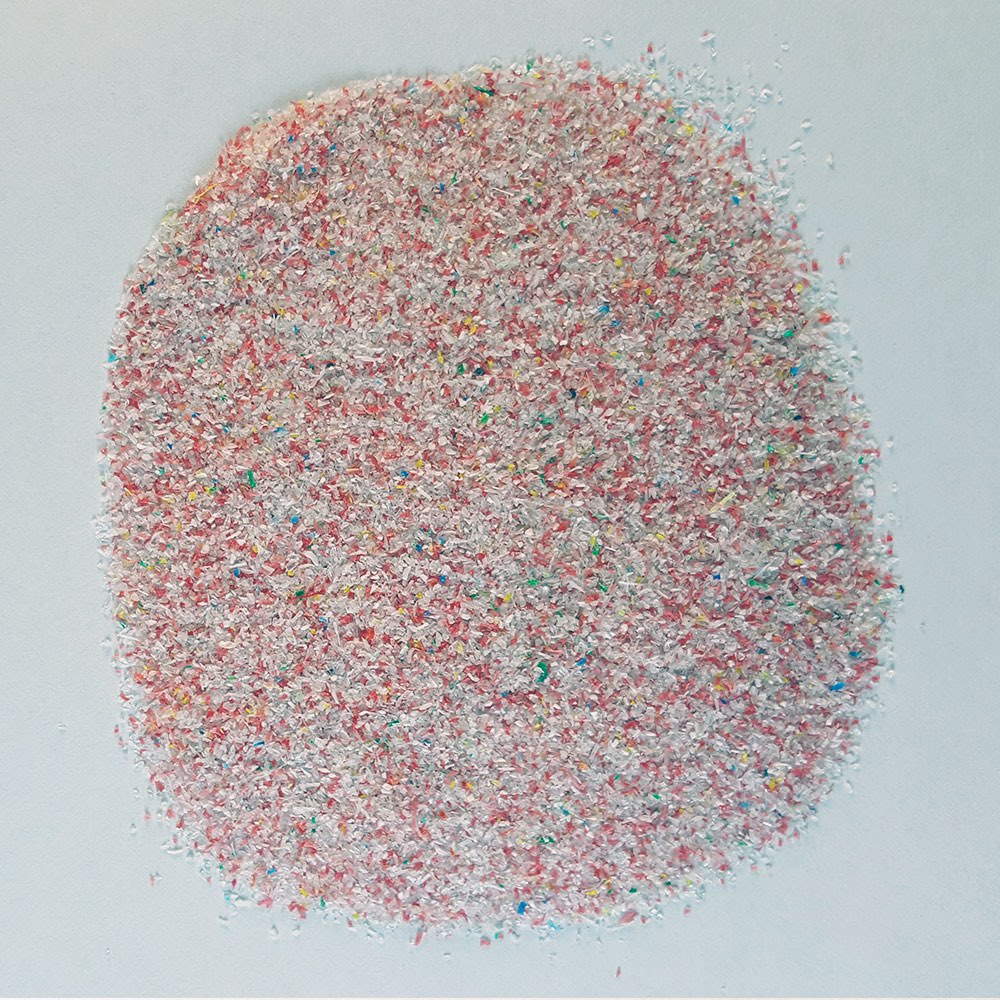

Acrylic (Type V) Plastic Abrasive Grit

Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts.

Acrylic (Type V) Plastic Abrasive Grit is the softest plastic media used for ultra-sensitive surfaces while still providing an effective strip rate. Acrylic Plastic Abrasive Grit is the longest lasting and is used for aircraft surfaces and delicate parts.

ACRYLIC (TYPE V) PLASTIC ABRASIVE GRIT

When your surface is delicate and you have high standards for surface finishing, acrylic (Type V) plastic abrasive grit is a very good option. Known as the softest of all plastic blasting media, this gentle yet effective material is tailor-made for precision work. With no heat involved and no damage, all you get is just the clean results you need.

Acrylic plastic has a purpose. Its softness is engineered to provide a solid strip rate while respecting the sensitive nature of your substrate. Be it that you’re working on aircraft exteriors or printed circuit boards, acrylic plastic abrasive grit stays cool under pressure and keeps your materials intact.

Unlike harsher abrasives, acrylic plastic media won’t gouge or distort fragile parts. It’s the preferred choice in industries where “delicate” goes hand in hand with durability and reusability. And because it doesn’t generate heat during blasting, warping and surface fatigue shouldn’t worry you.

Benefits

- Durable and Reusable

- Low Dusting

- Does not Generate Heat During Blasting

- Suitable for Multiple Substrates

- Meets MIL-P-85891

Applications

- Rubber Molds

- Urethane Bumpers

- Aircraft Engine Components

- Auto / Bus / Truck Bodies

- Trailers

- Helicopters

- Tanks

- Wheels

- Surface Sealants

- Airframes

- Aircraft Components

- Fiberglass Components

- Printed Circuit Boards

- Semiconductors

- Soft Metals Such as Aluminum and Magnesium

- Carbon Graphite Composites

- Axial Lead Diodes / Capacitors / Clear Optical Sensors

- Computer Housing Panels

- Copper Armature Wires

- Metal Die-Castings

- Steel

- Gears

- Tire Molds

- Actuator Assemblies

- and More!

Need to strip without stress and smoothen without a scratch? Acrylic plastic abrasive grit makes it happen for your parts.

It’s no surprise that this media is a mainstay in aerospace. It’s made to outlast and be quietly efficient and thoroughly effective. With the right touch, even fragile surfaces can get a fresh start without a scar.

Due to its non-conductive nature, acrylic plastic abrasive media is especially well-suited for blasting sensitive electronic components. They minimize the risk of static discharge or short-circuiting during surface preparation.

Conclusion

In a world of aggressive abrasives, acrylic plastic is designed for gentle action with maximum precision. This media is your route to clean and smooth finishes on even the most delicate components.

Need the right media for a sensitive part? Reach out to Kramer Industries—we’ve got the acrylic plastic abrasive grit that treats your parts with respect and gets the job done right. Strip softly and carry out a high-performance blast with acrylic plastic from Kramer.

Frequently Asked Questions (FAQs)

Q1. What is acrylic plastic abrasive grit?

Acrylic plastic abrasive grit is a lightweight, soft, and non-aggressive blasting media made from crushed acrylic plastic. It is used for precision cleaning, stripping, and surface preparation where surface protection is essential.

Q2. What are the key applications of acrylic plastic media?

Acrylic plastic grit is ideal for:

- Paint and coating removal from aircraft and vehicles

- Deflashing molded plastic parts

- Cleaning electronics or soft composites

- Surface preparation on delicate materials like aluminum and fiberglass

Q3. How does acrylic plastic media differ from other plastic abrasives like urea or melamine?

- Acrylic: Softest, ideal for thin coatings and soft substrates

- Urea: Medium hardness for general-purpose stripping

- Melamine: Hardest plastic grit, used for faster cutting on harder surfaces

Q4. What is the Mohs hardness of acrylic grit?

Acrylic plastic abrasive typically has a Mohs hardness of 3.0 to 3.5, making it very gentle on surfaces compared to mineral or metal abrasives.

Q5. Is acrylic plastic media reusable?

Yes. Acrylic grit is recyclable for multiple blasting cycles, depending on the blasting pressure, surface material, and recovery system used.

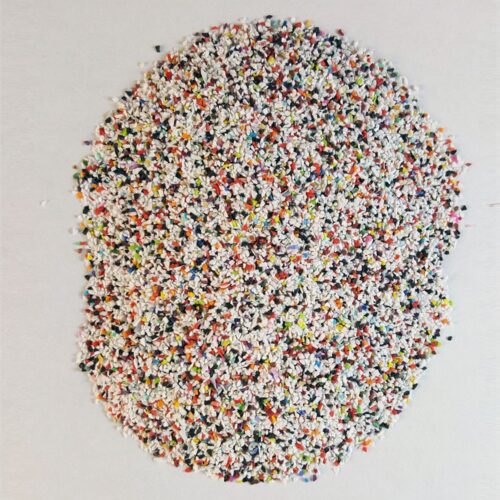

Related Products

-

Melamine (Type III) Plastic Abrasive Grit

$49.95 – $170.00 Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance.

Melamine (Type V) Plastic Abrasive Grit is the hardest plastic media used for applications that require a high strip rate without damage to the sub-surface. Melamine Plastic Abrasive is the perfect balance of speed and performance. -

Walnut Shell Blasting Media Grit

$39.95 – $105.00 Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media.

Walnut Shell Grit is a versatile, organic media. It is an angular media that is soft and sensitive to many surfaces. Walnut Shell Grit is an economical, biodegradable alternative for sensitive operations that require a moderately aggressive media. -

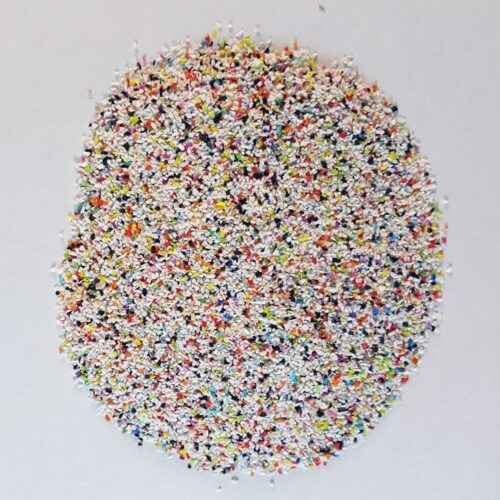

Urea (Type II) Plastic Abrasive Grit

$49.95 – $170.00 Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface.

Urea (Type II) Plastic Abrasive Grit is the most heavily used plastic media. Urea Plastic Abrasive Grit is used for applications such as auto and aircraft restoration to deliver an efficient strip rate without damage or warping of the substrate surface.