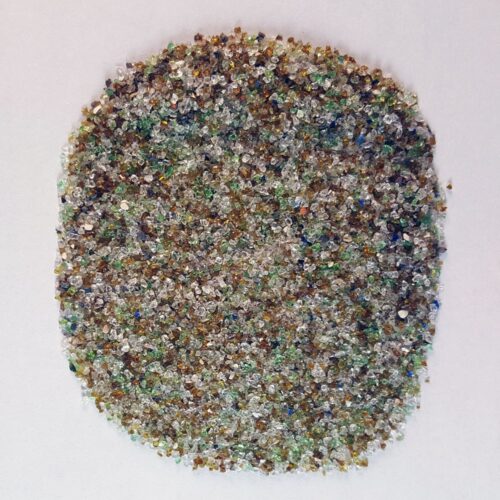

Copper Slag / Iron Silicate

Copper Slag also know as Iron Silicate is silica free, consumable abrasive blast media. It offers superior cutting and striping action leaving surface profiles ready to prime and paint. Ideal for large projects in shipyards, water tower blasting, pipe cleaning, and other heavy industrial paint striping applications.

Copper Slag also know as Iron Silicate is silica free, consumable abrasive blast media. It offers superior cutting and striping action leaving surface profiles ready to prime and paint. Ideal for large projects in shipyards, water tower blasting, pipe cleaning, and other heavy industrial paint striping applications.

Copper Slag / Iron Silicate

Copper Slag / Iron Silicate is ideal when a quick and efficient paint-stripping process is required. It produces a heavy to medium etch depending on the grade and leaves the surface to be primed and painted. This is a high-performance material trusted for heavy-duty blasting jobs across industries where you need to strip paint, rust, or scale fast.

Copper Slag is a consumable, silica-free premium alternative to silica sand. Used in everything from bridges to barges, iron silicate abrasive blasting delivers a deep etch and clean finish that’s ready for coatings. It has minimal dust and is strong enough to take on stubborn surface contaminants with ease.

Benefits

- Silica Free (less than 0.1%)

- Fast and efficient surface cleaning

- Very low dust

- Meets SSPC-AB1 and MIL-A-22262B (SH)

- Clean Surface Finish

- Surface profile from 2.0 to 5.0

- Efficient Blasting and Less Grit Used

Applications

- Rust, paint, and scale removal

- Bridge stripping and maintenance

- Barge and ship blasting

- Military vehicle and boat stripping

- Water tower stripping

- Surface preparation on new metal

- High-pressure water blast systems

Whether you call it copper slag or iron silicate abrasive, this media is all about performance without compromise. It cuts through buildup fast, leaves a clean profile, and doesn’t flood your workspace with dust. And because it’s a consumable abrasive, it’s ideal for one-time or high-turnover blasting projects.

Ready to blast through your toughest jobs with confidence? Kramer Industries offers premium copper slag/iron silicate abrasive blasting media built for power, speed, and safety. Shop our iron silicate abrasive solutions today.

Specifications

Copper Slag / Iron Silicate Specifications |

||

|---|---|---|

Grade |

Average Particle Sizethe smaller the mesh number, the coarser the grit |

Surface Profile (mils) |

| Coarse | 12-40 Mesh (0.425 – 1.7 mm) | 4.0 – 5.0 |

| Medium | 20-40 Mesh (0425 – 0.85 mm)) | 3.5 – 4.5 |

| Fine | 30-60 Mesh (0.25 – 0.56 mm) | 2.0 – 3.5 |

Frequently Asked Questions (FAQs)

Q1. What is iron silicate abrasive?

Iron silicate abrasive, also known as copper slag, is a by-product of copper smelting. It is a tough, angular blasting media used for cleaning, surface preparation, and removal of rust, paint, and scale from metal and concrete surfaces.

Q2. What are the key uses of iron silicate abrasive?

- Surface preparation for coatings or painting

- Rust, scale, and old coating removal

- Cleaning ship hulls, steel structures, tanks, and pipelines

- Concrete surface cleaning and profiling

Q3. What are the advantages of using iron silicate over other abrasives?

- High density for faster cutting action

- Low dust generation

- Non-hazardous and environmentally safer than silica sand

- Angular shape provides an excellent surface profile

Q4. Is iron silicate abrasive environmentally safe?

Yes. It is a by-product material that is non-toxic, free from crystalline silica, and safe to use in most industrial and marine environments. Always follow local disposal regulations.

Q5. Is iron silicate reusable?

A: While iron silicate is more durable than sand, it is generally used in single-pass applications. It can be reused a limited number of times depending on the system and contamination level.

Related Products

-

Garnet Grit Blasting Media

$39.95 – $87.00 Garnet Grit is a used for a wide variety of blasting applications. Used in both dry and wet abrasive blasting, Garnet Grit offers high performance and recyclability. The hardness and bulk density make this media ideal for general purpose surface preparation.

Garnet Grit is a used for a wide variety of blasting applications. Used in both dry and wet abrasive blasting, Garnet Grit offers high performance and recyclability. The hardness and bulk density make this media ideal for general purpose surface preparation. -

HDPPB Series – Heavy-Duty Grade, Portable Pressure, Abrasive Blasting System

$4,995.00The HDPPB Series is a Contractor Grade, Portable Pressure Blasting System designed for Heavy Duty Portable Sandblaster industrial applications of all kinds. Productivity and safety are engineered into the design of these systems.

-

KramBlast Crushed Glass Grit

$21.95 – $35.00 KramBlast Crushed Glass Grit is a silica-free, consumable abrasive that offers aggressive surface profiling and coatings removal. Manufactured from 100% recycled bottle glass, KramBlast Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives.

KramBlast Crushed Glass Grit is a silica-free, consumable abrasive that offers aggressive surface profiling and coatings removal. Manufactured from 100% recycled bottle glass, KramBlast Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives. -

Aluminum Oxide Abrasive Blasting Media Grit (Standard)

$39.95 – $244.50Aluminum Oxide Blasting Media Grit (Standard) is a sharp, long lasting abrasive media that is highly efficient and highly reusable. Harder than most blast media, Aluminum Oxide Blast Media, will clean and etch quickly on all type of surfaces.