Deburring may sound like a small finishing step, but it’s a very important part of making quality parts. Whenever a part is cut, punched, or machined, tiny sharp edges, called burrs, stay stuck to the surface. If you ignore these burrs, they can cause big problems. They can hurt workers, damage machines, and cause issues during assembly or coating. Automated deburring is simply the process of removing these unwanted edges using machines instead of doing it by hand.

A Multi-Tool Head Approach to Deburring

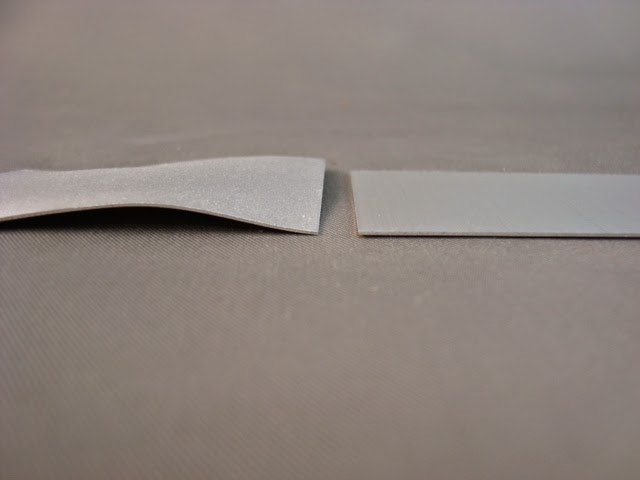

Flat deburring can be more complex than it seems. Just sending a part through a single-head machine doesn’t always make it burr-free. Often, small burrs on the front and back edges stay behind after the first pass. A wide-belt abrasive might remove one burr but leave a thin sharp edge that can still cut a worker’s hand. The best fix is a multihead setup. After the first abrasive head works, a rotating barrel brush spinning the other way gently removes the leftover burrs. What comes out is a smooth, safe-to-handle part ready for the next step.

Inside a flat-part deburring machine, several abrasive tool heads can work together. There might be wide-belt abrasives moving around a drum, cylindrical brushes sweeping across, and disc heads rotating over the surface. The hardness of these tools depends on the material type, its thickness, and the needed finish. A softer drum gives a smoother edge, while a harder one removes more material.

The Heart of Automated Deburring

Each run through an automated deburring machine is a careful balance. Material removal depends on the abrasive type, feed speed, motor power, and drum hardness. A soft brush gives a light, smooth edge, while a hard abrasive drum can remove more stock — up to about 0.001 inch or more.

Grit size also matters. Coarse grains cut deeper, while finer ones make a smoother shine. In a four-head machine, you might start with 60 grit for strong cutting, then use 100 and 150 grit for smoother results, and end with 180 grit for a fine No. 4 finish. But there’s no universal rule for what “No. 3” or “No. 4” finishes look like. That is because what’s ideal for an auto part might not be right for an appliance panel.

Machines with multiple heads and brushes can work in both directions. They can work with and against the feed to remove burrs from flat parts, even tiny grooves as small as 1/16 inch on laser-cut parts. Usually, two passes are enough to clean both top and bottom edges, though some machines can do both sides at once.

Workholding: The Silent Support

Even the most advanced automated deburring system needs a strong base. How the machine holds each part affects the final result. Conveyor systems can sometimes let small parts slip, causing incomplete deburring or even machine damage.

To prevent this, the part’s length should match the distance between pinch rolls so at least one roll grips it tightly. Small or thin parts can be tricky. If they’re too small, they can tilt or fall out.

Engineers have found smart fixes for this: attaching small parts to a skeleton frame, using vacuum beds that hold pieces with suction, or magnetic chucks that secure metal parts. Some systems use sticky belts to hold light items in place. The method depends on the material, part shape, and production size.

Wet vs. Dry: The Two Paths of Automated Deburring

Another choice comes when picking between wet and dry deburring machines. Dry machines are cheaper but need dust collectors. A dry collector works like a vacuum, while a wet collector traps dust in water to stop fire or explosion risks.

For carbon steel, dry systems work great. But for aluminum, wet deburring is a must because aluminum dust can catch fire easily. Wet systems remove this danger, as grinding dust mixes with water and coolants.

Wet machines also make abrasive tools last longer. A good coolant mix of 95% water and 5% chemical can nearly double the life of the media. Filters clean out the particles, letting the coolant be reused. Drying units with squeegees and air blowers remove any leftover water from the parts.

The Ease Behind the Complexity

Even though automated deburring deals with metal edges and grinding, it’s surprisingly easy to manage once set up. Changing a belt or adjusting for part thickness takes only a few minutes. An operator can switch belts in under three minutes or replace a brush in less than an hour.

After setup, parts move smoothly from cutting to deburring to assembly. No manual help is needed.

Finding the right setup takes some testing. You need to compare wet vs. dry systems, choose how many heads to use, select abrasives, and adjust feed speeds and brush hardness, all based on the material and finish needed.

When tuned correctly, automated deburring turns a manual job into a reliable, repeatable process. It doesn’t just smooth the metal; it makes production smoother too.

Benefits of Automated Deburring Machines

The advantages of automated deburring machines go far beyond smooth edges. Here’s why so many manufacturers now use them:

- Consistency: Every pass gives the same finish without depending on human skill.

- Safety: No more handling sharp edges or breathing abrasive dust.

- Speed: Parts finish in seconds, not minutes.

- Cost savings: Less labor, fewer rejects, and longer tool life mean higher profits.

- Versatility: Works with many materials: steel, aluminum, copper, and composites.

When set up well, automated deburring improves every step of production without being noticed.

Choosing the Right Automated Deburring Setup

Picking the right automated deburring system is about knowing your process, not just buying a big machine. If you work with thick steel plates, a strong multihead machine is best. If you handle small precision parts, you might need a vacuum bed or magnetic hold-down system. For aluminum, a wet machine with a good filter system is safest.

No one setup fits all. Testing different setups helps find the best one. Once tuned, the machine runs quietly, saving money and improving quality every time.

Conclusion

Automated deburring is one of the hidden heroes of modern manufacturing. It turns something rough and unsafe into something smooth, safe, and consistent. Whether it’s wet or dry, single- or multihead, it changes how factories finish their parts. It brings faster work, safer operations, and better-quality finishes every time.

Kramer Industries offers high-quality automated deburring machines built for reliable performance, safe operation, and excellent surface finishing. If you want to improve your workshop or production process, Kramer’s systems bring the smoothness and efficiency your products need.

Explore Kramer’s advanced finishing solutions today to get the perfect edge.